The more advanced the machines in the food industry become, the higher the need for in-depth training for operators. The VR training we created for VDAB teaches the trainee how the food sachet producing Smartpacker works and how it should be operated.

When we received a "Go!" from VDAB to develop the VR training, the first step was to learn all the ins and outs of the machine. By taking detailed pictures, recording videos, making sketches and talking to operators, our script writers and designers (almost) became specialists overnight.

Freedom of choice

In a 'true' VR training like this one, the trainee can freely move around in the virtual environment and decide at any stage to take a certain action... or not.

The storyboard needs to anticipate and react to every situation in the appropriate way. The complexity is therefore much higher than in a traditional linear course.

In close cooperation with our VR developers, the animation team built the 3D digital twin of the machine. It's fully operational and all relevant components can be manipulated by the trainee.

Step by step

The training consists of three stages:

- The working principle of the machine is explained by the voice-over while the trainee is guided around the machine; each step is shown and the trainee can try it out, before moving to the next step.

- The trainee has to set up the machine for running and is helped along the way whenever he/she gets stuck. Feedback is given when the operator makes a mistake.

- The trainee now has to prove that he is able to carry out the procedure. There is no guidance, because this step is the 'final quiz'.

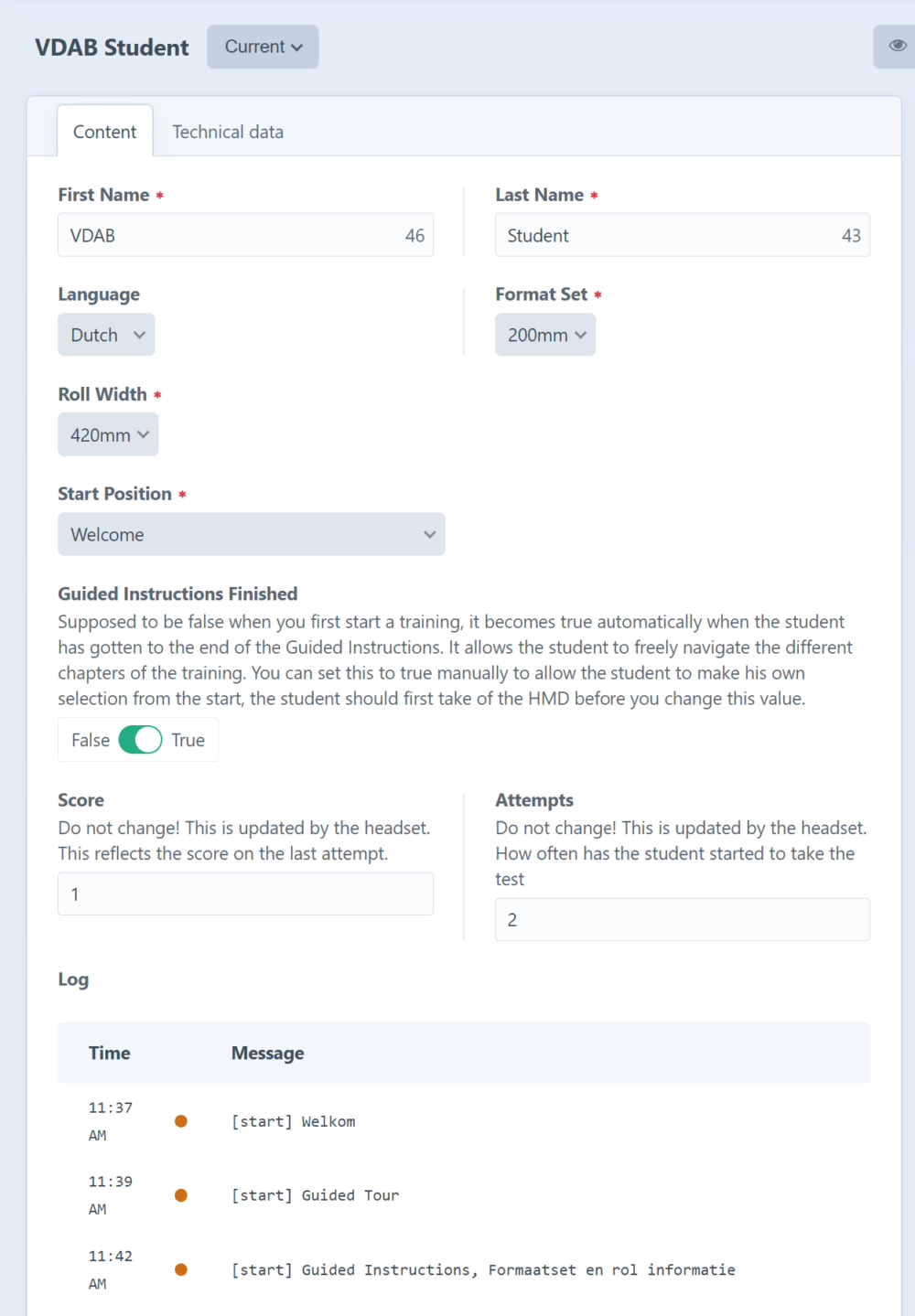

Throughout the training, everything is logged in the backend. All steps taken, mistakes made, retries, etc. can be consulted by the trainer for accurate feedback.

The spoken feedback during the training is a computer-generated voice, so the course is multilingual and easy to translate.